False Twist Texturing

show general information-

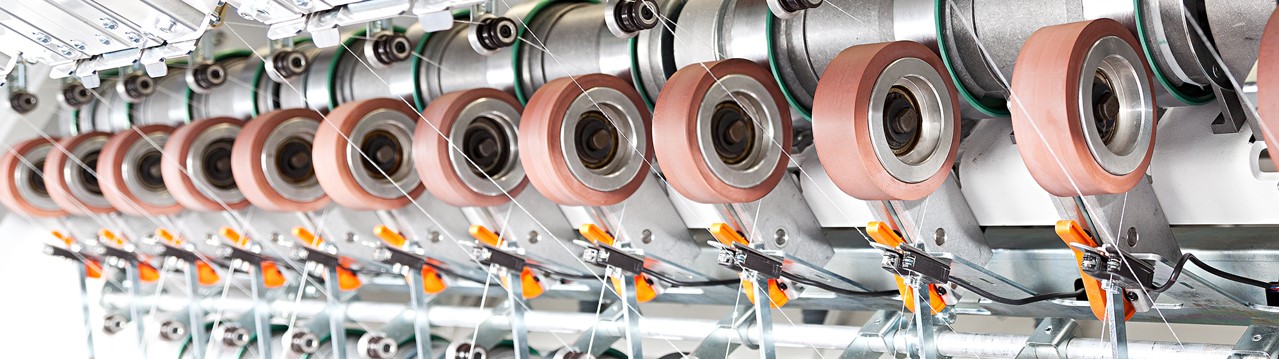

DP5-FT Automatic false-twist texturing machine

-

Tubes

or cops are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

-

FilamentYarnFilament Yarn

Synthetic yarn composed of one or more filaments that run the whole length of the yarn. Yarns of one filament are referred to as mono-filament; yarns of several filaments as multi-filament.

-

PPPolypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

-

PET / PESPolyester

Synthetic fiber made from a thermoplastic polymer that contain the ester functional group in their main chain. Most commonly refers to a type called polyethylene terephthalate (PET) or polyethylene succinate (PES) with a melting point from 103 – 106°C

-

ELElastan

Elastane or Spandex is a polyurethane-polyurea copolymer. This synthetic fibre can be stretched from four to seven times their length, reverting to their original length when the tension is relaxed. Used for all areas where a high degree of permanent elasticity is required: hosiery, underwear, sportswear, and in woven and knitted fabrics.

-

PAPolyamid

Also known as Nylon. PA consists of chemical fibres and are obtained from synthetic polymers. Polyamid is very resistant and tear proof as well as elastic, stretchable and takes just a little moisture up. In addition it is extensively crease-resistant and drip-dry.

-

POYPartially oriented yarn

Also known as Polyester POY, it is the primary form of Polyester yarn. POY is the first form of yarn made by spinning Polyester PET Chips. Mainly used for texturizing.

-

DTYDrawn Textured Yarn

Made from Polyester POY by simultaneously twisting & drawing. DTY yarn is mainly used in weaving and knitting.

-

PBTPolybutylene Terephthalate

PBT is similar to other thermoplasic polyesters. Compared to PET, PBT has a slightly lower strenth and rigidity, but a better impact resistance. The yarn has a natural stretch and can be incorporated into sports wear (most common found in swimwear).

Developed for the flexible production of fine to coarse counts (up to 1320 dtex) the SSM DP5-FT offers the high efficiency of multi density executions, along with the flexibility of individual drives. The ability to integrate two individual yarn paths per position enhances the capabilities of the machine. The basic modular machine concept allows it to be upgraded to changing market demands.

show more textshow less text

show more factsshow less factsTechnical data DP5-FT

Type of winding

DIGICONE® or precision

Mechanical speed

up to 1500 m/min (process speed dep. on process parameters and supply yarn/package)

Package shape

freely programmable on cylindrical tube

Initial traverse length

100…270 mm electronically adjustable

Take-up package diameter

up to 300mm

Package weight

up to 8 kg

Supply packages

(on rotary or trolley creel)– on rotary creel: 2 or 4 ends + reserve

– on trolley creel: 4 ends + reserve

– 290 mm tube length: up to ø 400 mm

– 150 mm tube length: up to ø 450 mmFibre material

Fibre structurePP, PA, PES, PBT

POYCount range

7…1320 dtex

Layout

N° of positions min./max.single sided

min. 5 / max. 40Drive

individually controlled single drives

Electrical power

(basic power supply)400 V, 50 cycles, 3 phases, loadable neutral, ground

(adaptable to other power supplies)Power consumption

– heating power consumption at 220 °C: 0.78 kW per position

– motor & electronic power consumption at 800 m/min: 0.54 kW per positionCompressed air requirement

– compressor with air dryer, oil filter and air tank

– pressure at 6 bar for process air and 6 – 9 bar for machine operation (doffer)Process air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Downloads

-

SSM_DP5-FT_gb.pdf

-

Tubes

-

TG2-FT False-twist texturing machine

-

Tubes

or cops are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

-

FilamentYarnFilament Yarn

Synthetic yarn composed of one or more filaments that run the whole length of the yarn. Yarns of one filament are referred to as mono-filament; yarns of several filaments as multi-filament.

-

PPPolypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

-

PET / PESPolyester

Synthetic fiber made from a thermoplastic polymer that contain the ester functional group in their main chain. Most commonly refers to a type called polyethylene terephthalate (PET) or polyethylene succinate (PES) with a melting point from 103 – 106°C

-

ELElastan

Elastane or Spandex is a polyurethane-polyurea copolymer. This synthetic fibre can be stretched from four to seven times their length, reverting to their original length when the tension is relaxed. Used for all areas where a high degree of permanent elasticity is required: hosiery, underwear, sportswear, and in woven and knitted fabrics.

-

PAPolyamid

Also known as Nylon. PA consists of chemical fibres and are obtained from synthetic polymers. Polyamid is very resistant and tear proof as well as elastic, stretchable and takes just a little moisture up. In addition it is extensively crease-resistant and drip-dry.

-

POYPartially oriented yarn

Also known as Polyester POY, it is the primary form of Polyester yarn. POY is the first form of yarn made by spinning Polyester PET Chips. Mainly used for texturizing.

-

DTYDrawn Textured Yarn

Made from Polyester POY by simultaneously twisting & drawing. DTY yarn is mainly used in weaving and knitting.

-

PBTPolybutylene Terephthalate

PBT is similar to other thermoplasic polyesters. Compared to PET, PBT has a slightly lower strenth and rigidity, but a better impact resistance. The yarn has a natural stretch and can be incorporated into sports wear (most common found in swimwear).

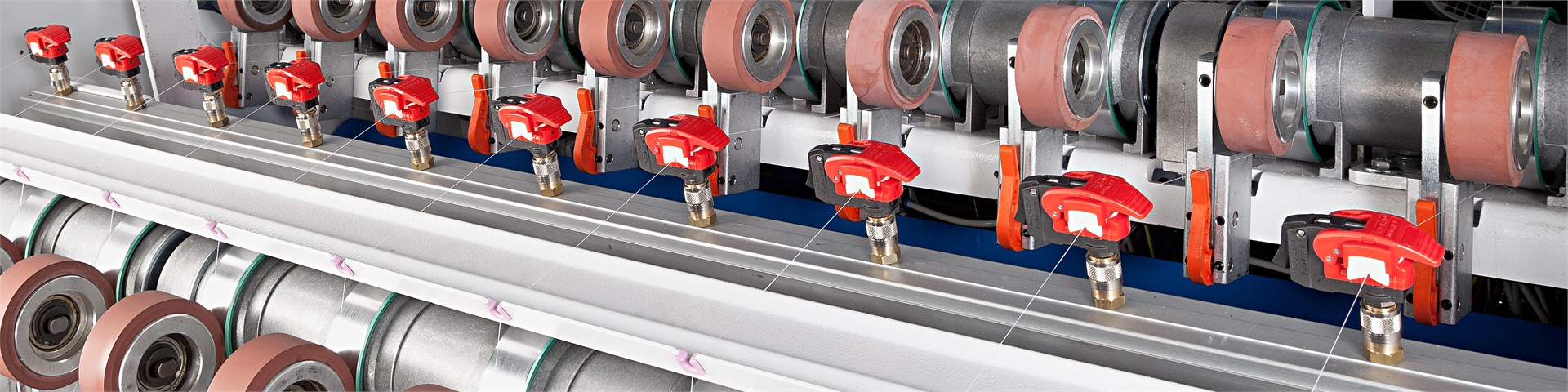

The TG2-FT false-twist texturing machine is the next step of the well introduced TG1. It comes with an individual, frontal doffing system to allow double-sided concept of the machine (one full package and one empty tube in the cradle whilst a package is being processed). The design is made for the cost efficient production of high quality Polyamide (down to 7 dtex), Polypropylene as well as fine count Polyester yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG2-FT

Type of winding

random

Mechanical speed

up to 900 m/min (process speed depending on process parameters, texturing jet and supply yarn quality)

Package shape

Cylindrical or bi-conical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 240 mm

Package weight

up to 5 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 450 mm, 250 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, PES, POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Double sided / min. 24 / max. 288

Drive

Split machine with individually controlled line shafts per side

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption (expected average at 175 °C and 800 m/min)

– DTY production: 0.31 kW per position

– DTY production incl. air covering: 0.38 kW per positionCompressed air requirement

Compressor with air dryer, oil filter and air tank pressure at 8 bar for machine operation and process air

Process air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Primary heater

140°–240°C

Downloads

-

SSM_TG2-FT_en.pdf

-

Tubes

-

TG1-FT Manual false-twist texturing machine

-

Tubes

or cops are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

-

FilamentYarnFilament Yarn

Synthetic yarn composed of one or more filaments that run the whole length of the yarn. Yarns of one filament are referred to as mono-filament; yarns of several filaments as multi-filament.

-

PPPolypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

-

PET / PESPolyester

Synthetic fiber made from a thermoplastic polymer that contain the ester functional group in their main chain. Most commonly refers to a type called polyethylene terephthalate (PET) or polyethylene succinate (PES) with a melting point from 103 – 106°C

-

ELElastan

Elastane or Spandex is a polyurethane-polyurea copolymer. This synthetic fibre can be stretched from four to seven times their length, reverting to their original length when the tension is relaxed. Used for all areas where a high degree of permanent elasticity is required: hosiery, underwear, sportswear, and in woven and knitted fabrics.

-

PAPolyamid

Also known as Nylon. PA consists of chemical fibres and are obtained from synthetic polymers. Polyamid is very resistant and tear proof as well as elastic, stretchable and takes just a little moisture up. In addition it is extensively crease-resistant and drip-dry.

-

POYPartially oriented yarn

Also known as Polyester POY, it is the primary form of Polyester yarn. POY is the first form of yarn made by spinning Polyester PET Chips. Mainly used for texturizing.

-

DTYDrawn Textured Yarn

Made from Polyester POY by simultaneously twisting & drawing. DTY yarn is mainly used in weaving and knitting.

-

PBTPolybutylene Terephthalate

PBT is similar to other thermoplasic polyesters. Compared to PET, PBT has a slightly lower strenth and rigidity, but a better impact resistance. The yarn has a natural stretch and can be incorporated into sports wear (most common found in swimwear).

The manual TG1-FT falsetwist texturing machine combines a proven texturing path along with a space saving machine design. The result is a machine for the cost efficient production of high quality Polyamide (down to 7 dtex), Polypropylene as well as fine count Polyester yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG1-FT

Type of winding

random

Mechanical speed

up to 1200 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

Cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 220 mm

Package weight

190 mm traverse length: up to 3.3 kg / 245 mm traverse length: up to 4.6 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 450 mm, 250 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, fine count PES, EL/POY

Count range

7...330 dtex

Take-up levels

4

Layout / N° of positions min. / max.

Double sided / min. 32 / max. 384

Drive

Split machine with individually controlled line shafts per side

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption (expected average at 175 °C and 800 m/min)

– DTY production: 0.31 kW per position

– DTY production incl. air covering: 0.38 kW per positionCompressed air requirement

Compressor with air dryer, oil filter and air tank pressure at pressure 8 bar for machine operation and process air

Process air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Primary heater

140°–240°C

Downloads

-

SSM_TG1-FT_gb.pdf

-

Tubes

-

TG.30 A Auto-doffing false-twist texturing machine

-

Tubes

or cops are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

-

FilamentYarnFilament Yarn

Synthetic yarn composed of one or more filaments that run the whole length of the yarn. Yarns of one filament are referred to as mono-filament; yarns of several filaments as multi-filament.

-

PPPolypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

-

PAPolyamid

Also known as Nylon. PA consists of chemical fibres and are obtained from synthetic polymers. Polyamid is very resistant and tear proof as well as elastic, stretchable and takes just a little moisture up. In addition it is extensively crease-resistant and drip-dry.

-

POYPartially oriented yarn

Also known as Polyester POY, it is the primary form of Polyester yarn. POY is the first form of yarn made by spinning Polyester PET Chips. Mainly used for texturizing.

-

DTYDrawn Textured Yarn

Made from Polyester POY by simultaneously twisting & drawing. DTY yarn is mainly used in weaving and knitting.

The TG.30 A false-twist texturing machine has been especially developed for the economic production of fine Polyamide and Polypropylene yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG.30 A

Types of winding

random

Mechanical speed

up to 1100 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 250 mm

Package weight

190 mm traverse length: up to 4 kg / 245 mm traverse length: up to 6 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 400 mm, 290 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP/POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Single sided / min. 12 / max. 168

Drive

individually controlled line shafts

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption

Heating power consumption at 220 °C: 0.19 kW per position

Motors & electronic power consumption at 800 m/min: 0.24 kW per positionRecommendation for compressed air /

process air requirementCompressor with air dryer, oil filter and air tank pressure at pressure 10 bar.

Consumption per doffing: 0.27 m3 per each complete doffProcess air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Compressed air

7 bar (machine operation including auto doffing)

Downloads

-

SSM-TG30A_gb.pdf

-

Tubes

-

TG.30 AEM Auto-doffing false-twist texturing and air covering machine

-

Tubes

or cops are the most flexible base for a wide range of package shapes (e.g.: cylindrical - no taper / biconical - double taper / single taper / bottle shape), depending on the winding unit (type of winding)

-

FilamentYarnFilament Yarn

Synthetic yarn composed of one or more filaments that run the whole length of the yarn. Yarns of one filament are referred to as mono-filament; yarns of several filaments as multi-filament.

-

PAPolyamid

Also known as Nylon. PA consists of chemical fibres and are obtained from synthetic polymers. Polyamid is very resistant and tear proof as well as elastic, stretchable and takes just a little moisture up. In addition it is extensively crease-resistant and drip-dry.

-

POYPartially oriented yarn

Also known as Polyester POY, it is the primary form of Polyester yarn. POY is the first form of yarn made by spinning Polyester PET Chips. Mainly used for texturizing.

-

PPPolypropylene (PP)

Polypropylene is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

-

ELElastan

Elastane or Spandex is a polyurethane-polyurea copolymer. This synthetic fibre can be stretched from four to seven times their length, reverting to their original length when the tension is relaxed. Used for all areas where a high degree of permanent elasticity is required: hosiery, underwear, sportswear, and in woven and knitted fabrics.

-

DTYDrawn Textured Yarn

Made from Polyester POY by simultaneously twisting & drawing. DTY yarn is mainly used in weaving and knitting.

The TG.30 AEM is especially designed for false twist texturing of fine and medium count PA and PP continuous filament yarns. In combination with the integrated elastomer unrolling device air covered yarns can be directly produced in one process step.

The main features are:

show more textshow less text

show more factsshow less factsTechnical data TG.30 AEM

Type of winding

random

Mechanical speed

up to 1100 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

Cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up package diameter

up to 250 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Package weight

190 mm traverse length: up to 4 kg / 245 mm traverse length: up to 6 kg

Supply package (on trolley creel)

up to 2 ends and stand-by per position:

– up to ø 400 mm, 290 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, EL / POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Single sided / min. 12 / max. 168

Drive

Individually controlled line shafts

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption

Heating power consumption at 220 °C: 0.19 kW per position

Motors & electronic power consumption at 800 m/min: 0.30 kW per positionRecommendation for compressed air / process air requirement

Compressor with air dryer, oil filter and air tank pressure at pressure 10 bar

Consumption per doffing: 0.27 m3 per each complete doffProcess air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Compressed air

7 bar (machine operation including auto doffing)

Downloads

-

SSM_TG30_AEM_en.pdf

-

Tubes

SSM - Leading Swiss technology for yarn processing and winding

SSM - Leading Swiss technology for yarn processing and winding