-

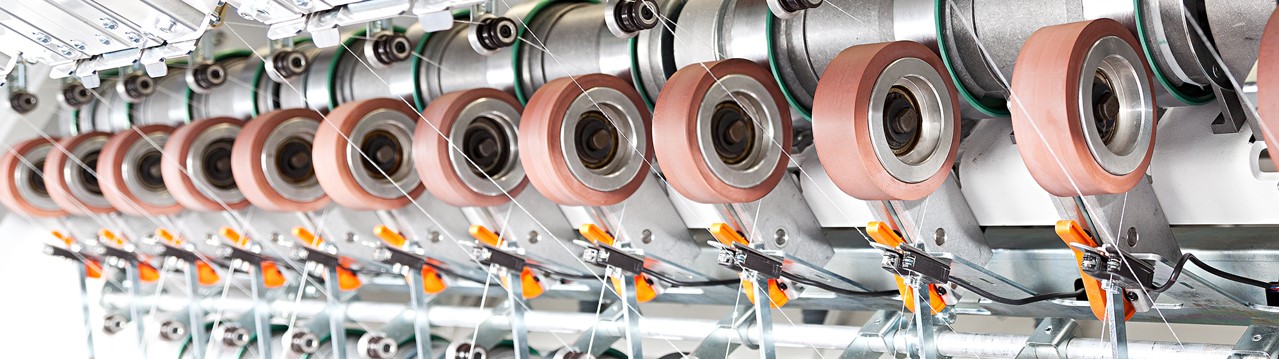

DP5-FT 全自动假捻变形机

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PET / PES聚酯

由热塑性聚合物制成的合成纤维。该聚合物在其主分子链上含有酯类官能团。通常指一种叫聚对苯二甲酸乙二醇酯(PET)或聚琥珀酸酯(PES)的聚合物,熔点从103 - 106°C。

-

EL氨纶

氨纶或斯潘德克斯弹性纤维是一种聚氨酯 - 聚脲共聚物。该合成纤维可拉伸长度四到七倍,当张力松驰后又回复至原始长度。应用在需要高度永久弹性的所有领域:裤袜,内衣,运动服,并用于机织物和针织物。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

DTY弹力丝

从POY进行同时加捻和牵伸而成。DTY丝主要用于机织和针织。

-

PBT聚对苯二甲酸丁二醇酯

PBT与其它热塑性聚酯相似。与PET相比,PBT强度和刚性略低,但更具抗冲击性。其纤维具自然伸展,可用于混织成运动服(最常见的是泳衣)。

DP5-FT 开发用于灵活生产细旦至粗旦(可达 1320 分特)纤维,提供多摩擦锭密度的高效率,以及独立驱动的灵活性。每位可合股二个独立丝道以提升机器产能。基础模块机器理念可使机器根据市场需求变化来升级。

show more textshow less text

show more factsshow less factsDP5-FT 技术数据

卷绕形式

数码卷绕或精密卷绕

机械速度

可达 1500 米/分 (工艺速度取决于工艺参数和原丝/卷装)

卷装形状

在平行筒管上可自由编程

初始横动长度

100…270 毫米电子可调

卷取卷装直径

可达 300 毫米

卷装重量

可达 8 公斤

供纱卷装

(在旋转丝架上或滑车式丝架上)– 在旋转丝架上: 2 或 4 股 + 备用

– 在滑车式丝架上: 4 股 + 备用

– 290 毫米筒管长度: 可达 ø 400 毫米

– 150 毫米筒管长度: 可达 ø 450 毫米纤维材料

纤维结构丙纶, 锦纶, 涤纶, PBT

POY纤度范围

7…1320 分特

机器布置

最少/最多位数单面机

最少 5个位 / 最多 4 0个位驱动

独立控制单独驱动

电功率

(基本供电)400 伏, 50 赫兹, 3 相, 可带荷载中线, 地线

(可适应其它供电)功率消耗

– 220 °C 时加热电耗: 每位 0.78 千瓦

– 800 米/分时马达和电子器件电耗: 每位 0.54 千瓦压缩空气要求

– 空压机,带空气干燥器,滤油器和气容

– 压力 6 巴用于工艺,6 – 9巴用于机器运行(落丝)压缩空气消耗

取决于喷嘴型号和变形工艺参数, 请参阅喷嘴制造商说明

Downloads

-

SSM_DP5-FT_cn.pdf

-

筒管

-

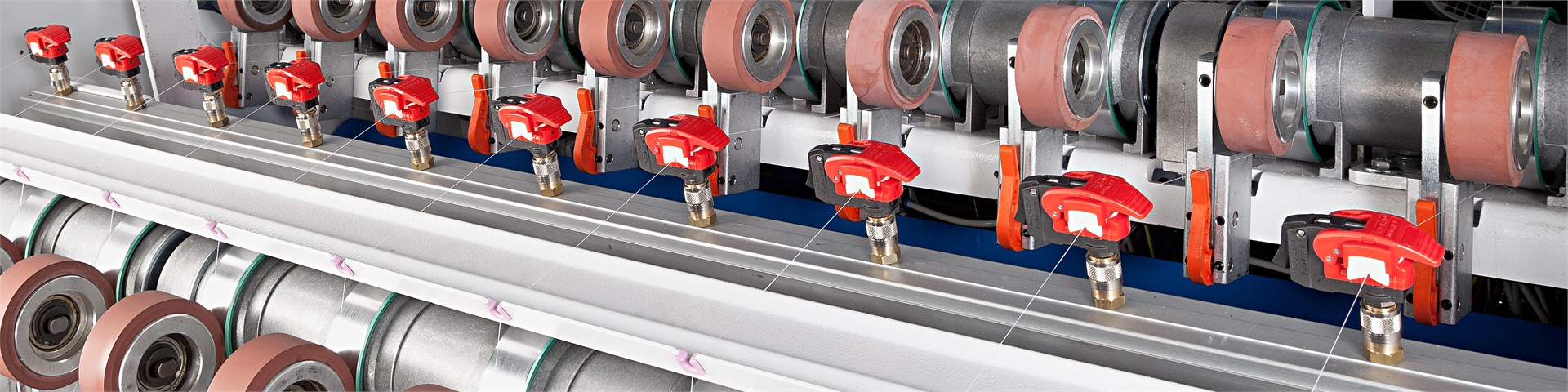

TG2-FT False-twist texturing machine

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PET / PES聚酯

由热塑性聚合物制成的合成纤维。该聚合物在其主分子链上含有酯类官能团。通常指一种叫聚对苯二甲酸乙二醇酯(PET)或聚琥珀酸酯(PES)的聚合物,熔点从103 - 106°C。

-

EL氨纶

氨纶或斯潘德克斯弹性纤维是一种聚氨酯 - 聚脲共聚物。该合成纤维可拉伸长度四到七倍,当张力松驰后又回复至原始长度。应用在需要高度永久弹性的所有领域:裤袜,内衣,运动服,并用于机织物和针织物。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

DTY弹力丝

从POY进行同时加捻和牵伸而成。DTY丝主要用于机织和针织。

-

PBT聚对苯二甲酸丁二醇酯

PBT与其它热塑性聚酯相似。与PET相比,PBT强度和刚性略低,但更具抗冲击性。其纤维具自然伸展,可用于混织成运动服(最常见的是泳衣)。

The TG2-FT false-twist texturing machine is the next step of the well introduced TG1. It comes with an individual, frontal doffing system to allow double-sided concept of the machine (one full package and one empty tube in the cradle whilst a package is being processed). The design is made for the cost efficient production of high quality Polyamide (down to 7 dtex), Polypropylene as well as fine count Polyester yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG2-FT

Type of winding

random

Mechanical speed

up to 900 m/min (process speed depending on process parameters, texturing jet and supply yarn quality)

Package shape

Cylindrical or bi-conical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 240 mm

Package weight

up to 5 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 450 mm, 250 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, PES, POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Double sided / min. 24 / max. 288

Drive

Split machine with individually controlled line shafts per side

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption (expected average at 175 °C and 800 m/min)

– DTY production: 0.31 kW per position

– DTY production incl. air covering: 0.38 kW per positionCompressed air requirement

Compressor with air dryer, oil filter and air tank pressure at 8 bar for machine operation and process air

Process air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Primary heater

140°–240°C

Downloads

-

SSM_TG2-FT_cn.pdf

-

筒管

-

TG1-FT Manual false-twist texturing machine

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PET / PES聚酯

由热塑性聚合物制成的合成纤维。该聚合物在其主分子链上含有酯类官能团。通常指一种叫聚对苯二甲酸乙二醇酯(PET)或聚琥珀酸酯(PES)的聚合物,熔点从103 - 106°C。

-

EL氨纶

氨纶或斯潘德克斯弹性纤维是一种聚氨酯 - 聚脲共聚物。该合成纤维可拉伸长度四到七倍,当张力松驰后又回复至原始长度。应用在需要高度永久弹性的所有领域:裤袜,内衣,运动服,并用于机织物和针织物。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

DTY弹力丝

从POY进行同时加捻和牵伸而成。DTY丝主要用于机织和针织。

-

PBT聚对苯二甲酸丁二醇酯

PBT与其它热塑性聚酯相似。与PET相比,PBT强度和刚性略低,但更具抗冲击性。其纤维具自然伸展,可用于混织成运动服(最常见的是泳衣)。

The manual SSM GIUDICI TG1-FT falsetwist texturing machine combines a proven texturing path along with a space saving machine design. The result is a machine for the cost efficient production of high quality Polyamide (down to 7 dtex), Polypropylene as well as fine count Polyester yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG1-FT

Type of winding

random

Mechanical speed

up to 1200 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

Cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 220 mm

Package weight

190 mm traverse length: up to 3.3 kg / 245 mm traverse length: up to 4.6 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 450 mm, 250 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, fine count PES, EL/POY

Count range

7...330 dtex

Take-up levels

4

Layout / N° of positions min. / max.

Double sided / min. 32 / max. 384

Drive

Split machine with individually controlled line shafts per side

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption (expected average at 175 °C and 800 m/min)

– DTY production: 0.31 kW per position

– DTY production incl. air covering: 0.38 kW per positionCompressed air requirement

Compressor with air dryer, oil filter and air tank pressure at pressure 8 bar for machine operation and process air

Process air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Primary heater

140°–240°C

Downloads

-

SSM_TG1-FT_cn.pdf

-

筒管

-

TG.30 A Auto-doffing false-twist texturing machine

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

DTY弹力丝

从POY进行同时加捻和牵伸而成。DTY丝主要用于机织和针织。

The TG.30 A false-twist texturing machine has been especially developed for the economic production of fine Polyamide and Polypropylene yarns.

The key features are:

show more textshow less text

show more factsshow less factsTechnical data TG.30 A

Types of winding

random

Mechanical speed

up to 1100 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Take-up package diameter

up to 250 mm

Package weight

190 mm traverse length: up to 4 kg / 245 mm traverse length: up to 6 kg

Supply package (on trolley creel)

1 end and stand-by per position:

– up to ø 400 mm, 290 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP/POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Single sided / min. 12 / max. 168

Drive

individually controlled line shafts

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption

Heating power consumption at 220 °C: 0.19 kW per position

Motors & electronic power consumption at 800 m/min: 0.24 kW per positionRecommendation for compressed air /

process air requirementCompressor with air dryer, oil filter and air tank pressure at pressure 10 bar.

Consumption per doffing: 0.27 m3 per each complete doffProcess air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Compressed air

7 bar (machine operation including auto doffing)

Downloads

-

SSM-TG30A_cn.pdf

-

筒管

-

TG.30 AEM Auto-doffing false-twist texturing and air covering machine

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

EL氨纶

氨纶或斯潘德克斯弹性纤维是一种聚氨酯 - 聚脲共聚物。该合成纤维可拉伸长度四到七倍,当张力松驰后又回复至原始长度。应用在需要高度永久弹性的所有领域:裤袜,内衣,运动服,并用于机织物和针织物。

-

DTY弹力丝

从POY进行同时加捻和牵伸而成。DTY丝主要用于机织和针织。

The TG.30 AEM is especially designed for false twist texturing of fine and medium count PA and PP continuous filament yarns. In combination with the integrated elastomer unrolling device air covered yarns can be directly produced in one process step.

The main features are:

show more textshow less text

show more factsshow less factsTechnical data TG.30 AEM

Type of winding

random

Mechanical speed

up to 1100 m/min (process speed depending on process parameters and supply yarn / package)

Package shape

Cylindrical or biconical

Initial traverse length

190 or 245 mm

Take-up package diameter

up to 250 mm

Take-up tube dimensions

Length 229 or 289 mm, ID 69 mm, rolled nose ID 57 mm

Package weight

190 mm traverse length: up to 4 kg / 245 mm traverse length: up to 6 kg

Supply package (on trolley creel)

up to 2 ends and stand-by per position:

– up to ø 400 mm, 290 mm tube length

or

– up to ø 450 mm, 150 mm tube lengthFibre material / Fibre structure

PA, PP, EL / POY

Count range

7...330 dtex

Take-up levels

3

Layout / N° of positions min. / max.

Single sided / min. 12 / max. 168

Drive

Individually controlled line shafts

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral, ground (adaptable to other power supplies)

Power consumption

Heating power consumption at 220 °C: 0.19 kW per position

Motors & electronic power consumption at 800 m/min: 0.30 kW per positionRecommendation for compressed air / process air requirement

Compressor with air dryer, oil filter and air tank pressure at pressure 10 bar

Consumption per doffing: 0.27 m3 per each complete doffProcess air consumption

depending on type of jet and texturing parameters, according to indication of jet manufacturer

Compressed air

7 bar (machine operation including auto doffing)

Downloads

-

SSM-TG30_AEM_zh.pdf

-

筒管

SSM - Leading Swiss technology for yarn processing and winding

SSM - Leading Swiss technology for yarn processing and winding